Progress in the CONI process

Łukasiewicz Research Network – Institute of Non-Ferrous Metals (Łukasiewicz–IMN) is responsible for the development and implementation of the CONI process within the framework of the METALLICO project. The main objective of this process is to recover valuable metals – copper, cobalt, and nickel – from the Fe-As alloy originating from the pyrometallurgical lead production process. Read more about their work in the last months to scale up the CONI process to pilot scale.

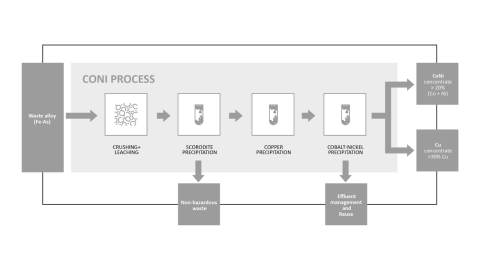

The CONI process comprises several unit operations, enabling selective recovery of the above-mentioned metals in form of two concentrates. Initially, the Fe-As alloy is leached, resulting in a solution containing iron, arsenic, copper, cobalt, and nickel. The next critical step involves a two-stage purification of this solution. In the first stage, arsenic and iron are removed by precipitation as scorodite (FeAsO₄·2H₂O), a non-hazardous waste that can be landfilled. In the second stage, the remaining iron and arsenic are eliminated in the form of iron and arsenic concentrate, which is returned to the scorodite precipitation stage. After purification of the solution, it is possible to selectively precipitate valuable metal concentrates as commercial products. First, copper is recovered as a carbonate concentrate of copper(II) (>30% of Cu). Then, cobalt is precipitated together with nickel in the form of a carbonate concentrate of cobalt+nickel (>20% of Co+Ni).

As part of the laboratory-scale research, the parameters of the individual unit operations that make up the CONI process were optimized and determined, i.e. leaching, arsenic and iron removal, precipitation of two concentrates. Currently, Łukasiewicz-IMN is undertaking preparatory activities to scale up the CONI process from the laboratory level (TRL 4) to the pilot scale (TRL 6). The existing pilot plant requires minor modernization, specifically the purchase and integration of a new reactor equipped with a mechanical stirrer. This reactor is a key component of the installation, as it will be used for the leaching of the Fe-As alloy and for the precipitation of arsenic and iron in the form of scorodite.

Pilot-scale tests will be carried out using the upgraded plant, which comprises the following components: semi-industrial jaw crusher, semi-industrial hammer crusher, four reactors, chamber-membrane filter press, and pressure filter. The commissioning of the CONI pilot plant will enable the validation and further optimization of the process parameters identified in the laboratory-scale studies.

As planned and envisaged in the METALLICO project, the capacity of the CONI pilot plant would be 100 kg/day. The implementation of the CONI process addresses the growing need for the recovery of critical metals from industrial residues in a manner that is both economically viable and environmentally sound. This approach contributes to reducing dependence on imported strategic raw materials and enhances the circular economy by promoting sustainable resource management.

Łukasiewicz–IMN at the International Copper Mining and Metallurgy Congress in Lubin

From June 4th to June 6th, 2025, Łukasiewicz–IMN, participated in the International Copper Mining and Metallurgy Congress held in Lubin, Poland. During the Congress, Joanna Malarz from the Centre of Hydroelectrometallurgy delivered a presentation titled "Recovery of Cu, Co and Ni from Fe-As alloy originating from the lead pyrometallurgical process." The presentation focused on the CONI process, with particular emphasis on the chemical and phase composition of the Fe-As alloy, as well as leaching studies of the Fe-As alloy using sulfuric acid solutions with the addition of oxidizing agents.