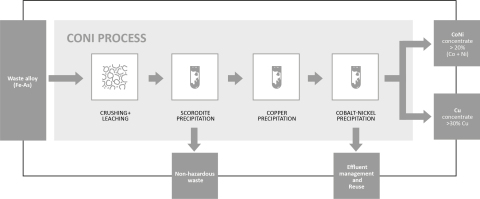

The CONI Process

The aim of the CONI process is to develop a technology for the recovery of copper, cobalt and nickel from waste alloys (containing iron-arsenic) that are generated in lead hydrometallurgical processes. This technology will allow to recover metals in forms which could be used for the production of cathodes for batteries.

The CONI process comprises several technical steps. The mechanical grinding of the waste alloy is followed by oxidative leaching in a sulfuric environment to dissolve copper, cobalt, nickel, iron and arsenic. After the removal of iron and arsenic from the solution copper is being recovered, followed by the precipitation of cobalt-nickel concentrate.