The Products of the CoNi Process: Copper and Cobalt-Nickel Concentrates

2 December, 2024

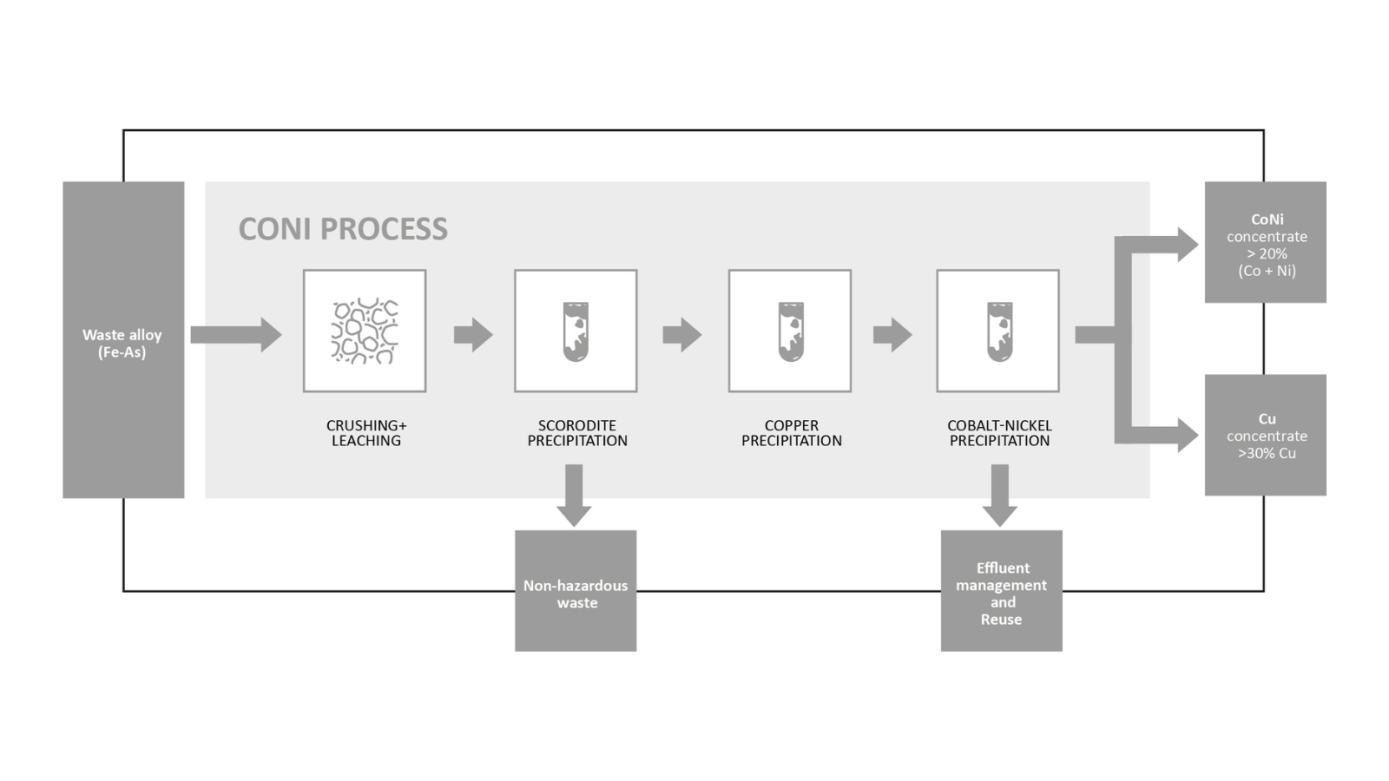

The CoNi process is carried out by the Łukasiewicz-IMN as a part of the Metallico project. This process concerns the recovery of metals such as copper (Cu), cobalt (Co), and nickel (Ni) from the iron-arsenic (Fe-As) waste alloy originating from the pyrometallurgical production process of lead. As part of the research, tests were carried out on the leaching of the Fe-As alloy, precipitation of iron (Fe) and arsenic (As) in the form of scorodite, and removal of the remaining amount of Fe and As. From the purified solutions after leaching, containing Cu, Co and Ni, two commercial products were obtained, specified in the METALLICO project proposal. Those were: copper(II) carbonate concentrate, with the chemical composition (%): 54.8 – Cu; 0.64 – Co; 0.31 – Ni, and also cobalt+nickel carbonate concentrate, with the chemical composition (%): 25.0 – Co; 0.25 – Cu; 14.5 – Ni. Additionally, a polymetallic carbonate concentrate of copper+cobalt+nickel was also precipitated, with the chemical composition (%): 17.3 – Co; 13.9 – Cu; 9.93 – Ni. The produced concentrates were tested by GLENCORE NIKKELVERK AS (GNN). The obtained results indicate a high potential for application of these concentrates in the production of battery cathodes.

Cobalt+nickel carbonate concentrate. @Carolina Goc, Łukasiewicz-IMN

Copper(II) carbonate concentrate. @Carolina Goc, Łukasiewicz-IMN

Copper+cobalt+nickel carbonate concentrate. @Carolina Goc, Łukasiewicz-IMN