IDENER: Scaling Up the METALLICO Project

From Laboratory Validation to Engineering Design

2 December, 2024

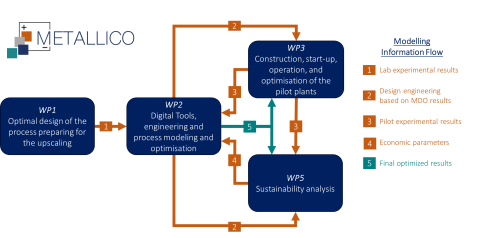

The METALLICO project is entering an exciting phase as we transition from laboratory-scale validation to the critical task of scaling up. After successfully validating and finetuned the five processes for battery metals recovery at the lab-scale, IDENER has now focused on moving toward pilot-scale operations, which is a key step of this project. This transition is guided by the engineering activities (which are supported by the modelling activities) led by IDENER with the support of other technical partners.

At this stage, the team is leveraging the mass balance data generated from the models to guide the design of the engineering systems required for pilot-scale operation. These mass balances provide us with the necessary information to estimate material flows, reaction kinetics, and separation efficiencies, ensuring that the scaling processes are efficient. By using this data, we can optimize the size and configuration of the equipment needed, while considering the specification of each process.

The engineering team is working closely together to ensure that the designs are not only technically sound but also economically viable. This integrated approach allows IDENER to evaluate different configurations and choose the most promising one, considering technological performance, required space for the pilot, operating mode (batch, continuous, or semi-continuous), and cost-effectiveness. The goal is to achieve an optimal design that will serve as the foundation for building and operating the pilot plants, which will then be tested for their real-world application.

As they are moving forward, the efforts are focused on delivering two key deliverables by December 2024, which will outline the progress on both:

- Modelling activities, including processes mass balances and preliminary optimization strategy

- Engineering designs, including all the required engineering documentation for processes upscaling (process description, process flow diagrams, piping and instrumentation diagrams, raw materials description, wastes and emissions, equipment list and datasheets, implementation plan, and safety study)

This is just the beginning, and IDENER is excited to see how the insights gained from laboratory validation will translate into large-scale operations that can drive the sustainable recovery of valuable metals from primary and secondary resources.