From Waste to value: Tharsis steps toward cobalt and manganese recovery

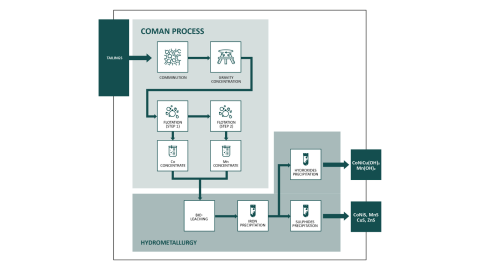

The COMAN process is focused on recovering cobalt (Co) and manganese (Mn) from secondary resources by Tharsis Mining. The process is divided into two main parts:

· Pretreatment, developed by Tharsis Mining (TM).

· Hydrometallurgical processing, carried out by VTT.

The pretreatment includes several steps: crushing and screening the material, grinding it, using flotation to separate copper and manganese, and finally filtering the concentrate.

To supply the pilot plant, three waste dumps from Tharsis were selected because they contain higher concentrations of copper, cobalt, and manganese. Over the past few months, 20 tonnes of ore have been collected and grinding of the material has already begun to ensure a steady feed to the pilot plant.

Meanwhile, Tharsis Mining has been building a pilot plant capable of processing 600 kg of material per day. Most of the equipment is already installed, but some components still need to be delivered and assembled in the coming months.. Despite this, separate tests have already been performed on the installed equipment, confirming that it operates correctly and allowing progress in the commissioning phase.

These tests also revealed two critical aspects of the process:

Grinding: To keep the flotation cells running continuously, a small stockpile of ground ore needs to be maintained. This prevents interruptions caused by unexpected delays or temporary staff shortages.

Concentrate filtration: Tests showed that the filtration system required greater capacity, so an additional filter press has been ordered. This new equipment is expected to arrive in Tharsis in the coming weeks.

Once all the equipment is on site, the start-up of the pilot plant will begin.