Coming soon: The TAILCO Pilot Plant

Throughout this year and into 2024, Cobre Las Cruces (CLC) and Cetaqua have been working on the construction and preparation of the TAILCO pilot plant. The goal is to complete all necessary arrangements for commissioning, start-up, and continuous operation in order to validate the technology developed over recent years.

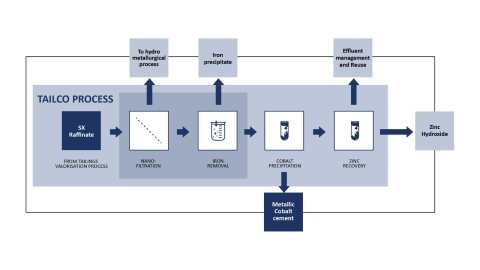

The TAILCO process enables the recovery of cobalt (Co) from tailings generated in copper (Cu) hydrometallurgical plants. It targets the raffinate produced during the solvent extraction stage, which contains valuable concentrations of cobalt and zinc (Zn). In the initial stage, nanofiltration is used to concentrate cobalt by a factor of four while simultaneously reducing acidity by recovering sulfuric acid (H₂SO₄), which can then be recycled back into the hydrometallurgical process. In the subsequent stage, impurities such as iron are removed via chemical precipitation. This is followed by selective recover cobalt in the form of a solid. Finally, the remaining zinc is precipitated and valorized due to its economic value, supporting a zero-waste approach.

The TAILCO pilot plant will include an initial nanofiltration stage (Figure 1), using a module developed by Cetaqua that is currently under construction and will be delivered to CLC for on-site installation. The subsequent process stages will utilize an existing pilot plant located at the CLC mine complex.

The existing pilot facilities at CLC (Figure 2) are being revamped to accommodate the main process equipment—such as tanks, reactors, thickeners, and filters—based on the expected process requirements. A detailed evaluation of the existing equipment was conducted using engineering documentation developed in a previous phase, including process flow diagrams, equipment lists, material balances, and piping and instrumentation diagrams. This evaluation helped identify the equipment best suited for the TAILCO process. Additionally, visual inspections, functional tests, non-destructive testing, and mechanical checks have been carried out.

Piping modifications and the arrangement of necessary pumping systems are critical tasks to ensure the process operates within the desired parameters. Electrical and instrumentation work, including the implementation of the control and monitoring system, is also underway to support efficient operation and data management. A key activity for pilot operation is the development of an operating manual, which is currently in progress and will include procedures for start-up, normal operation, safety instructions, and more.

As final conclusion it can be stated that the TAILCO process is progressing according to schedule, and the pilot plant is expected to be ready for commissioning in September 2025.

.jpg)