Advancing the PURGES Process: Sustainable Cobalt Recovery

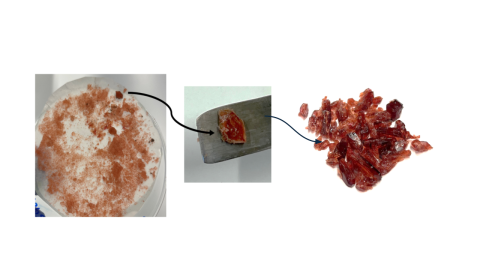

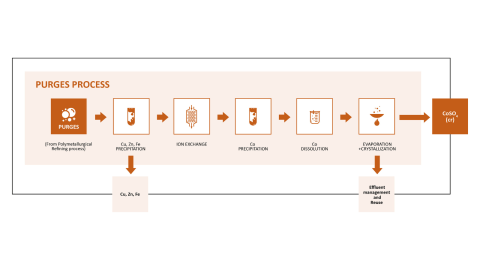

In recent months, METALLICO partners have achieved some progress in developing the PURGES process. This process is one of METALLICO’s innovative solutions for the valorisation of the polymetallurgical refinery (PMR) waste from from Cobre Las Cruzes (CLC). The objective of the PURGES process is to demonstrate the feasibility of recovering cobalt for further production of battery cathodes.

Over the past few months, CLC has been focused on building a pilot plant that will allow them to test this process, working closely with the supplier to make sure everything stays on schedule and reach the standards of quality.

The PURGES pilot plant, developed by Cetaqua-Water Technology Centre, will treat synthetic liquid waste using a specially designed system that operates at a flow rate of 150 liters per hour. The first phase of the pilot will test different conditions to find the most effective way to run the process. During this stage, CLC plans to treat about 24 cubic meters of synthetic solution over an estimated period of 8 weeks. Once the best conditions are found, the second phase will begin.

This will involve running the plant continuously at optimal settings to confirm the expected performance, aiming to treat between 12 and 36 cubic meters of solution over 4 to 12 weeks. In preparation for this important step, CLC is collecting detailed information on the equipment used, which will help to conduct safety assessments and prepare operational manuals. All these efforts bring CLC closer to demonstrating how PURGES can make processes cleaner and more sustainable.