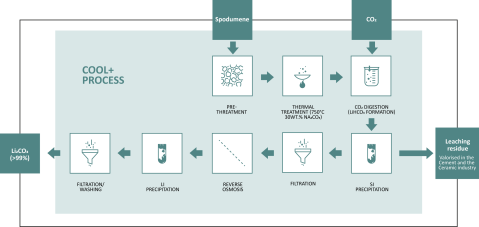

The COOl+ Process

The goal of the COOL+ Process is the selective recovery of lithium as well the production of geopolymers from the aluminosilicate solid residue and thus a holistic valorisation (zero-waste concept) of lithium containing ores.

In a first step the lithium ores are mixed with 30 wt.% Na2CO3 and thermally treated at 750 °C. Afterwards, the material is suspended in water and leached with supercritical CO2. The liquid phase contains lithium hydrogen carbonate, but also co-mobilised Na+, Al3+ and Si4+. Si4+ in particular must be removed to prevent membrane clogging. Therefore, MgO is added after leaching to form poorly soluble magnesium silicates. These are removed together with the leaching residue by filtration.

The filtrate is concentrated by reverse osmosis. Through evaporation lithium carbonate (Li2CO3) is precipitated and washed with water to obtain a highly pure product.

Since the lithium concentration in the raw material is low (< 5 wt.%) the main part of the ore remains as solid after leaching. In the framework of a zero-waste concept this residue is used in the cement industry.