Case Study 2: TAILCO and PURGES Processes for Secondary Sources (Co) Exploitation

In case study 2, the TAILCO and the PURGES processes are applied.

The TAILCO process aims to recover cobalt (Co) from secondary resources (tailings). These were produced by Cobre Las Cruces (CLC) in its current hydrometallurgical plant from secondary copper production which started in 2009. Feed material for the process is the raffinate generated from the existing solvent-extraction circuit after copper recovery. This contains interesting concentrations of cobalt and zinc in an aqueous sulphuric acid media.

The TAILCO process will also be developed by CLC and will suit the existing processing route applied on tailings reprocessing. The overall process integration will be necessary to ensure efficient use of contained resources.

Next steps

CLC will start by developing lab fine-tuning activities to achieve the optimal operating conditions of the process. This will serve as base to develop the definition of the pilot-scale to demonstrate the process. Finally, cobalt products obtained in the pilot plant will be validated for the use in the battery industry.

The PURGES process will be developed by CETAQUA and aims to recover cobalt from purges generated during polymetallurgical refining processes. PURGES will employ a route based on ion-exchange resins to achieve ionic extraction and selectively recover cobalt while minimising the required amounts of environmentally friendly solvents. In the next step, the concentrated cobalt and sulphuric acid (H2SO4) stream will undergo evaporation and crystallisation to obtain valuable cobalt(II) sulphate (CoSO4) as a final product.

The process will be developed to treat zinc raffinate from CLC Polymetallurgical Refinery (PMR) project.

Next Steps

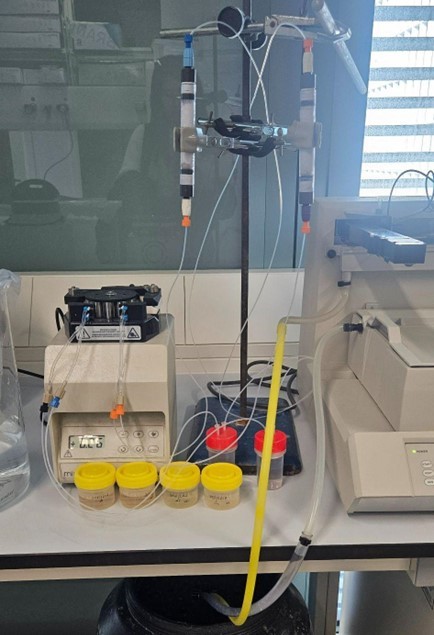

At the moment, CETAQUA (via UPC) is in the process of identifying the most appropriate resins available in the market for this purpose. This involves conducting lab experiments with synthetic samples to eliminate manganese, calcium, zinc, Copper, and iron from the feed. Currently, two of six ion exchange resins are undergoing sequential testing for this specific objective. The chosen resins will undergo validation in order to proceed with the pilot upscaling