Case Study 1: COOL+ Process for Primary Sources (Li) Exploitation

Case Study 1 is about the optimisation and demonstration of the COOL+ process for the recovery of lithium (Li) from lithium-containing raw materials such as spodumene. The core of the COOL+ process is the leaching of the ore with supercritical CO2. To improve mobilisation rates, the material is thermally treated prior to leaching to convert the lithium-containing phases into α-spodumene. This facilitates mobilisation.

During leaching with CO₂, lithium is mobilized in the form of lithium hydrogen carbonate, but also Na⁺, Al³⁺, and Si⁴⁺. To prevent membrane clogging during further processing, Si4+ is removed from the liquid phase as poorly soluble silicates by adding MgO. To isolate the target product lithium carbonate, only a concentration by reverse osmosis and subsequent precipitation by raising the temperature is required. As a result, battery-grade lithium carbonate is obtained after washing the crude product with water.

Since the lithium content in the ores is very low and is accompanied by a large proportion of gangue material, the processing of this gangue material is essential to create an economically and ecologically sensible process. In the COOL+ process, this is done by using residues in cement industry. This approach avoids direct stockpiling of the residual material, reducing associated costs and environmental risks, while generating usable construction products.

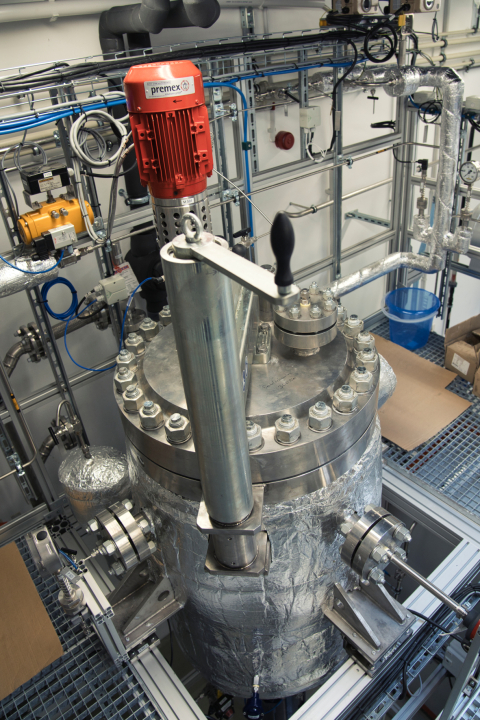

In the METALLICO project, the COOL+ process is first optimised on a laboratory scale by TU Bergakademie Freiberg and then transferred to a pilot plant (6 kg ore per day) by Fraunhofer Institute for Ceramic Technologies and Systems IKTS. Based on this, another pilot plant (1 t ore per day) will then be built by Idener.

Next steps

Laboratory-scale optimisation has been successfully completed, and preparations for the full pilot plant are now in progress. Once the pilot plant is operational, the laboratory findings will be validated under larger-scale conditions.

Advantages of the process:

- Selective lithium recovery

- Applicable to a wide range of raw materials

- Material utilisation of CO2

- Low chemical consumption

- Isolation of battery-grade lithium carbonate with minor purification steps

- Use of leaching residue for the cement industry

- Complete recycling of the starting material, no waste

- The entire process can be run on electricity, so there is no need for fossil raw materials at all

- Simple water treatment