Tharsis Mining: Contributing to circular economy through revalorization of mining waste

In a world where the development of an environmentally friendly and sustainable economic system has become increasingly important in recent decades, waste reuse is one of the key points to achieve this goal.

One of the main goals of METALLICO is to recover critical raw materials, such as battery metals, from secondary resources, contributing to the circular economy. Thus, increasing the production of these target metals and making use of European resources are important pillars of this project.

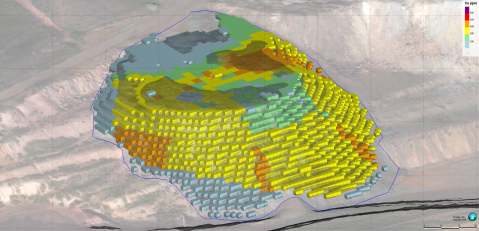

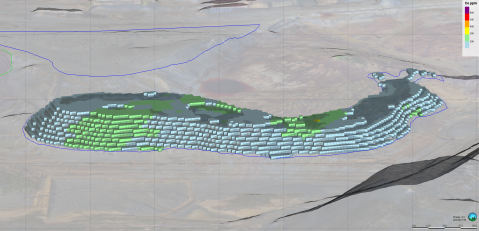

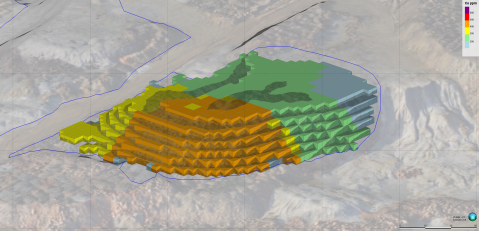

In this context, Tharsis Mining is working with other partners on the COMAN process where mainly cobalt (Co) and manganese (Mn) will be recovered from Tharsis secondary resources (Figure 1). Some crucial compounds will be obtained and finally used in the production of metallic cathodes in the battery industry. Thus, in order to develop an efficient treatment, a deep characterization of the Tharsis mine waste is essential. In addition, this information will be part of the battery metals inventory, a database that will be created during the course of this project.

For that purpose, Tharsis Mining has carried out a physical and chemical characterization of mine waste. Specifically, their density, tonnage and chemical composition were determined and used for modelling the dumps, that is a creation of a 3D distribution model in which metals concentration is easily observed.

Figure 1: Tharsis secondary resources.

By now, the characterization of the MW 3, MW 5 and MW 9 dumps have been accomplished. In these secondary resources, remarkable concentrations of several valuable metals have been detected, such as cobalt and manganese, but also copper, lead or zinc.

Figure 2 shows cobalt distribution models for the dumps previously mentioned, where blue and green coloured parts represent the lowest cobalt concentrations and purple and red ones have the highest metal concentrations.

Currently, different analyses are being conducted to further characterise the mining waste dumps. At the same time, Tharsis is involved in laboratory tests of the COMAN process, which will determine the optimal operating results that will ultimately be used to scale up this treatment.

Figure 2: Co distribution models for selected MW’s

Image source: Tharsis Mining