Meet the Partners: Fraunhofer IKTS

What are your main tasks in the project?

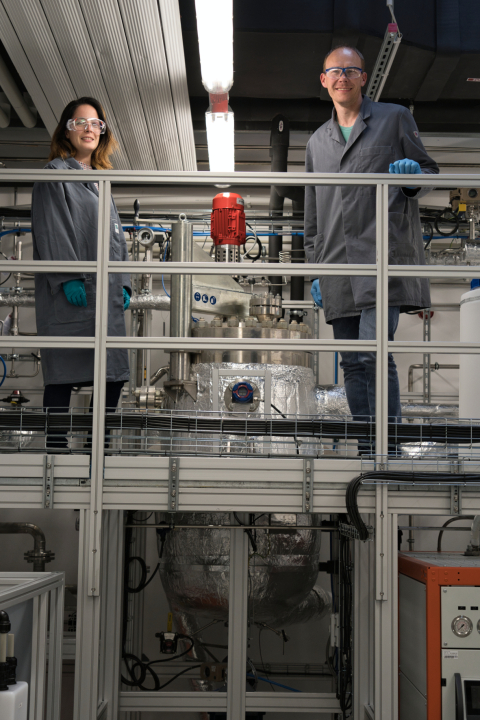

Fraunhofer IKTS will validate the COOL+ process in pilot-plant scale, which integrates the selective recovery of lithium from primary raw materials as well as the production of geopolymers from the aluminosilicate solid residue.

By including additional units to the existing COOL-pilot plant, this efficient recycling process which allows the production of Li2CO3 in battery grade, will be optimized for different lithium ores. The solid residue produced after the digestion with CO2 will be evaluated for the production of sustainable construction material like geopolymers.

What are your next steps in the project?

For our next steps, we will work together with TU Bergakademie Freiberg (TUBAF): They will carry out the optimization of the lithium recovery. We will perform preliminary experiments in the COOL pilot-plant using the most efficient parameters provided by TUBAF. Our focus will be on the validation of the process, investigating whether the leaching efficiency is scalable and, if needed, modifying parameters to reach the highest lithium recovery as well as the highest Li2CO3 purity in pilot-plant scale.

Why do you think METALLICO is important for the general public?

In our everyday lives, lithium-ion batteries are everywhere: E-bikes, cellphones, laptops or powertools. Not to mention the thousands of electric vehicles that are available today. Critical metals such as lithium, nickel, cobalt and copper are needed to manufacture these essential batteries. We depend on supply because most of these metals' deposits and production are located outside of Europe. METALLICO demonstrates different strategies and processes to recover these metals from both primary and secondary sources from Europe, thus contributing not only to safeguard the basis of critical raw metals but also to achieve a circular economy.