Building the Brains Behind METALLICO: A Digital Twin For Metals Recovery

The METALLICO project is taking an important step toward the digitalisation of metal recovery processes. Over the past months, IDENER has started building a web-based platform that will act as the “Digital Twin” of the METALLICO process. But what exactly is a Digital Twin?

Imagine having a virtual version of a pilot plant, where you can test different scenarios, change operating conditions, and see how the system behaves. That’s what a Digital Twin does. It brings together data, models, and interactive tools to simulate real processes in a digital environment. In METALLICO, this tool will help researchers and engineers explore how different recovery processes work, optimise performance, and make better decisions.

So far, IDENER has completed the first development phase of this tool. One of the most important achievements is the design of the platform’s architecture. Following a modular and scalable approach, the system is being built using open-source technologies and container-based solutions. In simple terms, each part of the platform is like a Lego block that can be developed and improved independently. This makes it much easier to grow, adapt, and integrate with the work from other teams in the project.

The technology behind the platform combines powerful tools from the world of software engineering and data science. The interface you see on your screen (the “frontend”) has been created using Blazor, a web framework that allows interactive applications to run in the browser. For the backend (the part of the system that handles data, models, and calculations) IDENER uses FastAPI, a high-performance Python framework that connects the models with the user interface. Everything is wrapped into containers using Docker, which makes the platform easy to deploy on different computers or in the cloud.

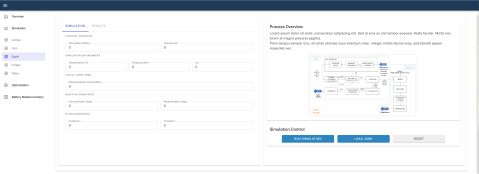

The first version of the platform is already live in its basic form. It includes a home page, a navigation menu, and the first elements for running simulations and visualising results. Users will be able to log in, select a process, run a model, and see how the system reacts. This will help them test ideas and explore “what if” questions.

One of the key goals is to connect this tool with other components of the project. For instance, it will link with the digital inventory of raw materials developed in another task, so that users can see how the availability of metals affects recovery efficiency or environmental impact. The final platform will include dashboards to visualise all this information in a clear and simple way.

Picture: Template of the digital twins interface, developed by IDENER. @IDENER